SDLG RS8160 Road roller single-drum vibratory road roller

RS8160

Product Introduction

The RS8160 is a mechanical single-drum vibratory road roller designed for heavy-duty compaction tasks, making it highly effective for compacting diverse soil types and rock fill. This self-propelled road roller stands out in the industry due to its superior compacting performance, driving capabilities, maneuverability, and overall reliability. It is especially suited for constructing high-quality infrastructure such as highways, airports, ports, railways, embankments, and industrial areas.

1.Engine: The roller is powered by a Weichai Deutz engine, renowned for its substantial power output and about 18% reduction in fuel consumption compared to previous models. The engine is engineered for high reliability and includes a starting enrichment feature to enhance its performance.

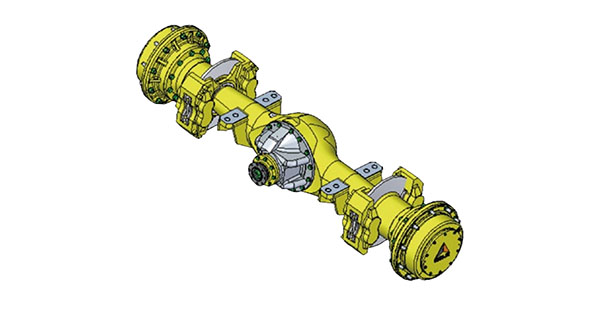

2.Drive Axle: The RS8160 incorporates a reinforced drive axle from SDLG, designed to handle greater loads and provide exceptional reliability, ensuring long-term durability and operational stability.

3.Transmission: Featuring a mechanical countershaft transmission, the roller has three forward gears and two reverse gears. It is equipped with a synchronizer system that allows for smooth gear transitions and includes neutral start and reverse warning functions for added safety and ease of use.

4.Vibratory Components: The machine uses a PERMCO vibratory pump and motor, known for their stable quality and reliability. These components are critical for maintaining consistent compaction performance across various materials.

5.Frame Structure: The RS8160’s frame is constructed from high-quality sheet metal and welded for structural integrity. This design ensures an even distribution of load, resulting in a high loading capacity and robust performance.

6.Articulated Frames: The front and rear frames are joined by a slewing ball bearing, which facilitates easy disassembly and assembly. This design reduces maintenance needs and enhances overall reliability.

7.Exciting Mechanism: SDLG’s patented exciting mechanism provides uniform amplitude and frequency on both sides of the vibratory drum, contributing to efficient and effective compaction. High-quality vibratory bearings are used to support significant loads and ensure stability.

8.Radiator System: The radiators are arranged in a linear configuration to optimize heat dissipation. A sealed partition separates the cooling and heating areas, improving the overall cooling efficiency of the machine.

9.Throttle Control: The ratchet-controlled hand throttle allows operators to set and maintain a constant speed for the vibratory function, optimizing the vibratory pump’s power and enhancing compaction results.

10.Cab Design: The cab of the RS8160 is designed for comfort and visibility, with a spacious and bright interior that features excellent sealing. An air conditioning system and ergonomic layout ensure a pleasant working environment.

11.Electrical System: The road roller’s electrical system is centralized, featuring a digital instrument panel for improved human-machine interaction and ease of maintenance. This setup ensures effective monitoring and control of the machine’s functions.

12.Engine Hood: The engine hood is operated by an electrically-controlled linear actuator, allowing for easy one-button opening. This design provides ample access for maintenance and service, with a wide opening angle for convenience.

13.Optional Features: The RS8160 can be equipped with optional OTR tires and pad-feet, allowing for customization to meet various operational needs and working conditions.

Product parameters

Nominal amplitude (mm) |

1.8/1.0 |

Minimum outside steering radius (mm) |

6400 |

Vibration frequency (Hz) |

30 |

Maximum gradability |

30% |

Exciting force (kN) |

305/170 |

Static line load (N/cm) |

368 |

Forward I(km/h) |

0~2.4 |

Forward Ⅱ(km/h) |

0~4.7 |

Forward Ⅲ(km/h) |

0~9.9 |

Forward Ⅳ(km/h) |

- |

Reverse I (km/h) |

0~2.4 |

Reverse II(km/h) |

0~4.7 |

Reverse III(km/h) |

- |

Reverse IV(km/h) |

- |

Overall length (mm) |

6113 |

Vibration pump width (mm) |

2130 |

Overall width (mm) |

2300 |

Wheel track |

- |

Overall height (mm) |

3140 |

wheelbase(mm) |

3303 |

Minimum ground clearance (mm) |

350 |

Total mass (kg) |

16000 |

Swing angle(°) |

- |

- |

- |

Engine model/Drive Motor Model |

WP6G160E201 |

Number of cylinders |

6 |

Engine type |

In-line、 water-cooled、 four-stroke、 direct injection |

Bore/stroke(mm) |

105/130 |

Engine power (KW) |

118 |

Minimum fuel consumption(g/kW.h) |

≤220 |

Rated engine speed(r/min) |

2000 |

Maximum torque (N.m)/rotation speed (r/min) |

600 |

Displacement (ml) |

6750 |

Emission standard |

GB 20891-2007 |

Clutch type |

Single-disc dry clutch |

Specification of driven disc |

380 |

Separating force (N) |

3630 |

Pressing force (N) |

14800~16500 |

Separating stroke (mm) |

10 |

Transmission type |

Counter-shaft mechanical shift |

Shifting gears |

forward 3 reverse 2 |

Gear ratio of transmission forward I |

9.22 |

Gear ratio of transmission forward Ⅱ |

4.72 |

Gear ratio of transmission forward Ⅲ |

2.23 |

Gear ratio of transmission reverse I |

9.318 |

Gear ratio of transmission reverse Ⅱ |

4.708 |

Gear ratio of transmission reverse Ⅲ |

- |

Model of variable-speed pump |

- |

Working pressure of shifting(MPa) |

- |

Main drive type |

First reduction of spiral bevel gear |

Main drive reduction ratio |

5.286 |

Wheel reduction type |

One-stage planetary reduction |

Wheel reduction ratio |

4.941 |

Type of drive axle |

RWD |

Tyre size |

23.1-26-12PR |

Rear tyre pressure(MPa) |

0.2 |

Type of foot brake |

Air-over-oil caliper disc brake |

Brake pressure (MPa) |

0.6~0.8 |

Parking brake type |

Manual caliper disc brake |

- |

- |

Type of steering system |

Full hydraulic steering gear |

Steering pump model |

flow:60 L/min |

Steering pump displacement |

- |

Steering cylinder - bore x rod diameter x stroke |

100×45×282 |

Steering gear |

BZZ6-500A full hydraulic steering gear |

Steering gear displacement |

- |

Steering angle (°) |

35° |

Working pressure of steering system(Mpa) |

16MPa |

Vibration mode |

Open-type system |

Vibration system manufacturer |

PERMCO (Tianjin)、huarun |

Vibration pump model |

P7600-F100N0367 6G |

Vibration pump displacement (mL/r) |

99.4 |

Vibrating motor model |

M7600-F112J |

Vibrating motor displacement (mL/r) |

116 |

Model of walking pump |

- |

Displacement of walking pump (ml/r) |

- |

Model of front travel motor |

- |

Displacement of front travel motor (ml/r) |

- |

Model of rear travel motor |

- |

Displacement of rear travel motor (ml/r) |

- |

Reducer model |

- |

Reducer gear ratio |

- |

Fuel filling capacity(L) |

270 |

Oil filling capacity of axles (main drive and wheel reducer)(L) |

16L+2×5L |

Hydraulic oil filling capacity(L) |

130L |

Transmission oil filling capacity(L) |

15 |

Engine oil filling capacity(L) |

16 |

Oil filling capacity of braking system(L) |

2 |

Filling capacity of water radiator antifreeze coolant |

- |

Gear oil filling capacity of vibrating drum vibration chamber |

- |

GET FINANCING!

Grow Your Fleet & Increase Your Revenue

Wheel Loader

Wheel Loader

Excavator

Excavator

Motor Grader

Motor Grader

Backhoe Loader

Backhoe Loader

Road Roller

Road Roller

Spare Parts

Spare Parts